|

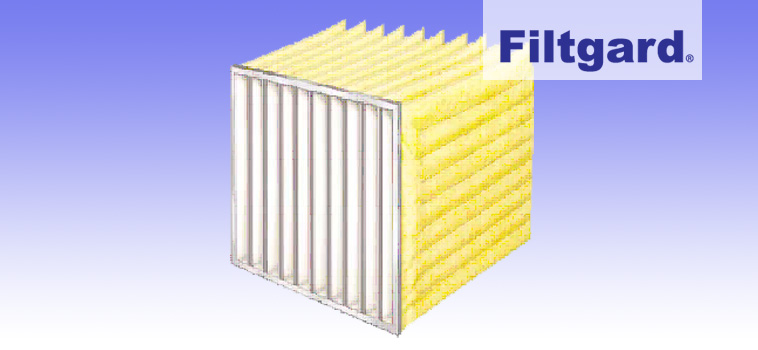

Pocket Filter

Filtgard® Pocket Filters manufactured with synthetic media are particularly well suited for applications where use of fiberglass media may be restricted, such as high humidity or where moisture is present.

Features & Benefits

-

100% Synthetic Media

-

Sonic Welded Pocket Construction

-

Five Efficiencies – Color Coded

-

Low Resistance

-

Unaffected by High Humidity or Moisture

-

Media will not Support Microbial Growth

-

Rugged Construction

-

U.L. Class 1

Dual Layer Meltblown Synthetic Media Holds More Dirt

Filtgard filters are made with dual layer high loft synthetic media for maximum dust holding capacity at each efficiency.

Upstream Layer – A meltblown facing on the air entering side protects the final filter layer and prevents erosion.

Final Filter Layer – A high loft meltblown final filter layer provides high efficiency and high dust holding capacity with low resistance.

Scrim backing – A high strength spun bonded scrim backing on the air leaving side protects the media and provides durability to the pockets.

Triple Seal Ultrasonic Welding Creates High Burst Strength

Filtgard pockets are formed by an ultrasonic sealing process that securely bonds the layers of media creating high burst strength. Pocket integrity is maintained at high resistance or under turbulent conditions.

For extra protection agains pocket failure, the ultrasonic sealing process is applied in a triple weld pattern. Fail safe operation is assured under all operating conditions.

Applications

Widely used as a permanent washable filter in place of metal filters or disposable panel filters in HVAC equipment, including:

-

Hospitals

-

Food Processing

-

Pharmaceutical Production

-

Paint Spray Booths

|

-

Schools

-

Office Complexes

-

Public Arenas

-

General Industrial

|

|

|

|